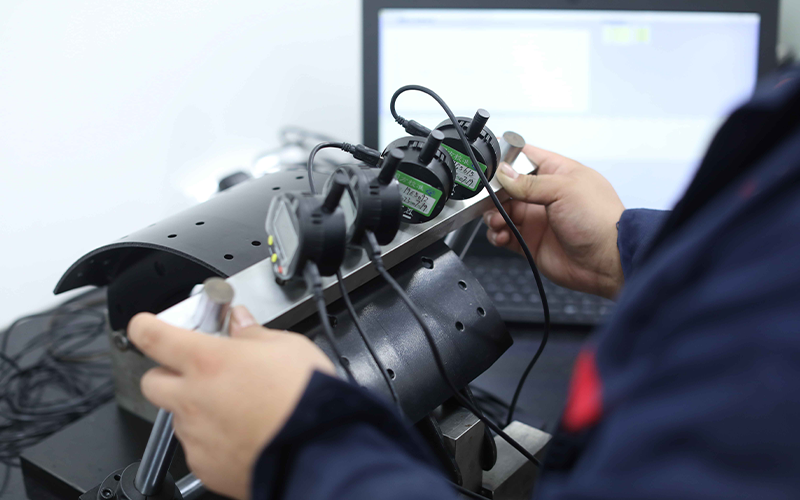

Quality Control

Equipped with professional inspection facilities and advanced quality control capabilities, and adopted strict quality control processes to ensure each product is rigorously inspected and meets customers’ requirement and standard.

Automatic Image Measuring Instrument

Automatic Inspection Line for Distinguish Thick and Thin Lining

Brake Lining Strength Destruction Tester

Coating Thickness Tester

Coordinate Measuring Machine (CMM)

Lined Brake Shoe Cylindrical Grinding Machine

Radian Detector

Rockwell Hardness Tester

Roughness Tester 2

Roughness Tester

Salty Spray Tester

Vickers Hardness Tester

Welding Destruction Tester

OUR ADVANTAGES

◎

All Brake Shoe is developed based on OE drawings or OE samples;

Well acknowledged of all products’ technical requirements, and meet OE’s requirements and standard.

◎

The raw material is sourced from premium and stable suppliers to ensure Brake Shoe quality.

◎

Specializedequipment is used to ensure high quality of Brake Shoe. For example, we use self-developed Rolling machine to make a smooth curve shape of platform that Brake Lining can fit perfectly.

◎

Automatic Welding Machine and Automatic Riveting Machine are used to improve welding and riveting quality.

◎

Brake Shoe end slot is heat treated to improve hardness, strength and wear resistance of material;

Use specialized equipment to ensure Brake Shoe has the required hardness and depth, meanwhile minimizes the heat treatment distortion.

◎

Unique surface treatment that allow all Brake Shoe can reach over 504hrs in ASTM B117 Salty Spray Test.

◎

Different Surface Treatment can be provided for customers’

OUR LINING

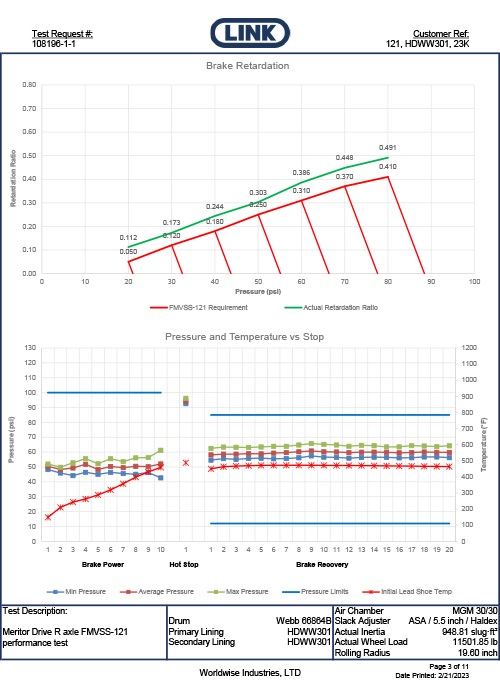

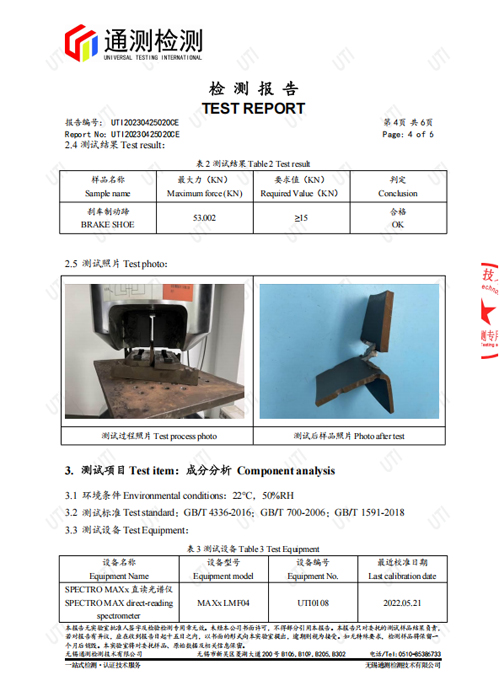

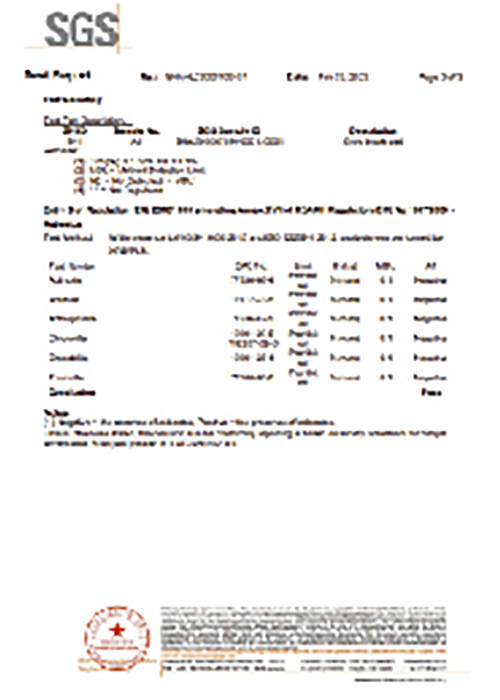

01. ECE R90 Certificate for European market;

02. FMVSS121 Testing by Link or Greening Test for American and other market;

03. Lining Grade: 20KFF, 23KFF, 26KFF

Brake Lining Performance

Our Lining Suppliers

Zhejiang Safe Technology Co., Ltd. has built a long-term relationship with well-known Brake Lining suppliers, to offer more choices for customers.